Drum Crafting Process at a Glance

Raw Materials

Long-term relationships with suppliers help Heng Chao guarantee a reliable supply and wide selection of quality veneers. Choose from conventional materials such as birch, maple, basswood and poplar, exotic hardwoods like African Mahogany, or our exclusive MESAWA timber.

Shell Construction

Heng Chao helps clients customize drum sound and appearance by matching different veneers, varying ply thickness and applying different joining techniques. Extensive appearance in shell formation and bonding methods provides clients with an unlimited number of options.

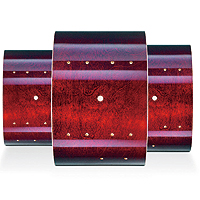

Finish

Heng Chao provides an extensive and growing range of lacquer, polyurethane coatings and PET plastic wraps. Lacquered drums are UV-cured in a state-of –the art clean room to ensure against impurities and defects, and polyurethane coated shells are ‘air-dried’ for a full week. Custom colors and finishes and other custom artwork are also available.

Bearing Edge

In order to help further differentiate each client’s final product, Heng Chao provides, as standard service, the production of a custom bearing-edge cutting-die for each product series. Sound quality and consistency are further

ensured through routine die maintenance and replacement.

Assembly

Work areas and tools are specially-designed to maximize efficiency and reduce mistakes, while detailed production checklists help spot even the smallest of defects. Heng Chao’s assembly-line process not only increases speed and efficiency, but also benefits quality control.

Packaging

Heng Chao’s advanced packaging system minimizes both cost and potential for damage during shipment by calculating the most effective use of space and designing impact foam inserts for secure fits. Heng Chao can also ship direct-to-retail (drop ship) in single-box sets available in black and white or four-color (CMYK) printing.